Mechanics

Each mechanical tool has different features and need of cooling depending on its type, method of metal-working and principle of operation:

Cutting metal-working

This machining process produces a lot of heat that has to be taken away with a “cutting fluid” to prevent dimensional tolerances variations or total loss of the working parameters. For cooling cutting fluids we recommend special chillers designed and perfectly suitable for these purposes.

Automation and hydraulics

In these systems it is necessary to take away heat, emitted by the hydraulic pumps, into oil, and to maintain the temperature in the circuit with the help of oil refrigerants to avoid problems with mechanical thickening of oil.

Machine-tools with spindles

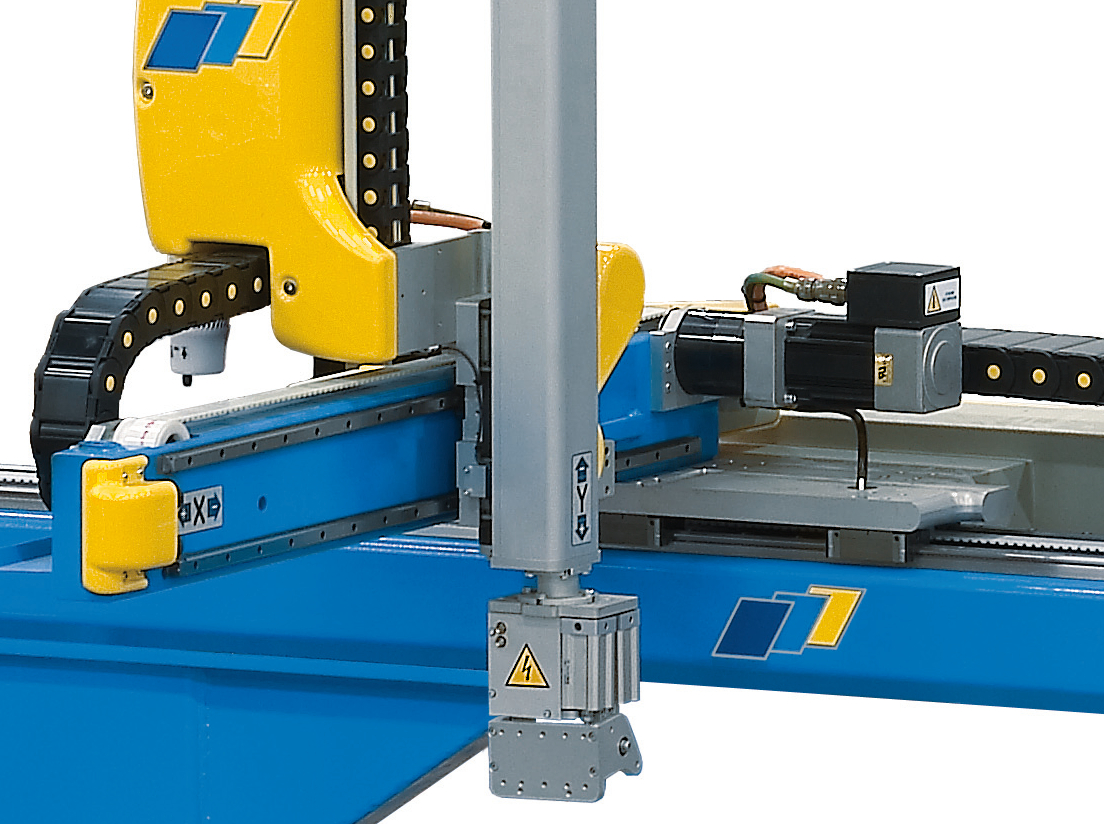

Linear motors and torque motors

Linear motors and torque motors need to be water-cooled.

Laser cutting machines

Laser machines require precise cooling and temperature control of the working fluid (demineralised or deionised water depending on the laser type) or the laser machine-tool will not work at all.

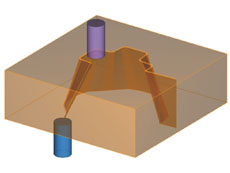

EDM machines

EDM machining process takes place in dielectric fluids and allows to produce components of different complex configuration with high precision. In the process of machining a lot of heat is dissipated in the fluid which must be taken away with the help of water chillers.