Written 70 years ago. Determination of leakage of freon in refrigeration units

11.09.2019

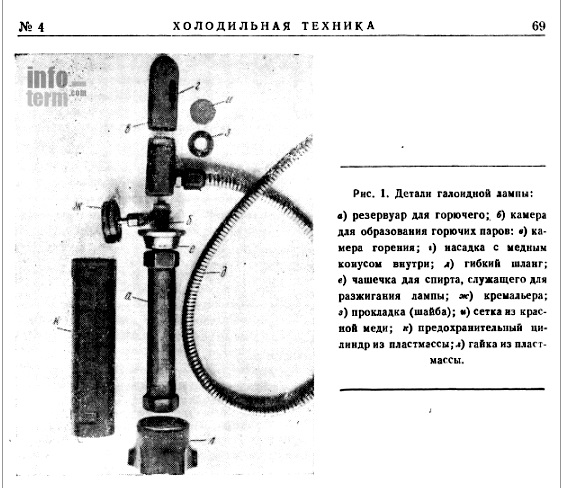

In freon refrigeration units, the location of the leak is determined using a halide lamp. The lamp consists of the following parts (Fig. 1}:

a) a fuel tank,

6) chambers for the resulting combustible vapors,

c) combustion chambers for the formation of combustible vapors and decomposition of freon,

d) nozzles with a copper cone, where there is an effect on copper of chloride and hydrogen fluoride gas obtained from the thermal decomposition of freon. In this case, gadondic compounds of copper are formed, which, evaporating, color the colorless flame in the lamp in a zeonous color,

d) a flexible hose for suction of freon in places of leaks,

f) cups in which alcohol is pressed to kindle (warm up) the burner. The tank has a cotton wool wick for supplying fuel to the steam chamber.

It is necessary to use the lamp in this way: first fill it with fuel, for which you need to unscrew the lower nut made of plastic (with a brass nut inserted into it), turn the lamp over with the open hole up and pour methyl alcohol (clean, halogen free}, leaving some space empty .

Then tighten the nut, preliminarily: by checking if there is a cliterite gasket on it, otherwise the alcohol may leak out after further heating.

Then pour methyl alcohol into a cup, approximately 34 containers with, and light. During the combustion of alcohol, the chamber warms up and the vaporization of the fuel takes place. That is why it is impossible to pour alcohol into the tank, and it is necessary that there is room for the formation of vapors and the creation of pressure.

Towards the end of the burning (burning) of alcohol in the cup, turn the spindle rack and turn the escaping methanol vapor through the slot (window) in the upper nozzle of the lamp. Combustion of methyl alcohol vapor gives a colorless flame if it contains no halide impurities.

Wine (ethyl) alcohol should not be consumed for combustion, since more heat is generated during its combustion than in methyl alcohol.

The lamp must be lit in a room that does not contain Freon and other gasoid vapors, such as chloroforua, carbon tetrachloride, chloroethane, etc. The indoor air must also not have г halogen-containing acids, for example, hydrochloric acid and free gas liquids like chlorine, bromine and node. All of these substances give galondny volatile compounds of copper, which color the lamp flame in green (nitric acid copper stains in blue-blue).

The determination of freon leakage is as follows. With a burning lamp, they approach the place where they want to determine the leak of freon in a hose hole is applied to it. If there is a leak, burning vapors suck in air containing freon, the latter decomposes with the formation of hydrogen chloride and fluoride, which, with further advancement, come into contact with the copper cone and cause the formation of volatile halide copper compounds and color the flame green.

The absence of a green color of the flame indicates that there is no leakage of freon. Large freon leaks at the spindles of the venlyles, compressor bearings, in the cracks of cast iron, etc., can cause a flame color that does not disappear for a long time.

In the event of a mesh breakdown, improper combustion occurs in the lamp, so the mesh must be replaced with a new one.

Klingerite gaskets should be clean, not contaminated with chloride salts or hydrochloric acid.

Contamination may interfere with the normal operation of the lamp and require disassembly for cleaning. Alcohol must not have any mechanical impurities that may cause clogging of the piston hole. To clean the latter, a needle is used, attached to the device (such as a primus).

To determine the halide contamination in methyl alcohol, a small piece of copper oxide should be taken with tweezers, calcined in a flame of pure alcohol, allowed to cool, then pour 1-2 drops of the tested alcohol and introduced into the flame of pure alcohol. The absence of green color of the flame will be a guarantee of its purity.