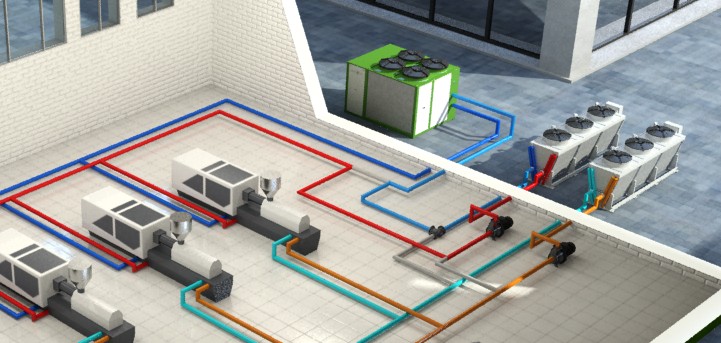

Double centralized circuit with two independent temperatures

This type of circuit is used to provide two independent water temperatures, to chill different users with:

- one circuit designed to chill low temperature users (such as moulds) using water chillers;

- one circuit designed to chill

medium-high temperature users (such as the hydraulic systems) using free-coolers;

Benefits:

the free-coolers provide water/brine cooling without any compressor, thus performing energy saving

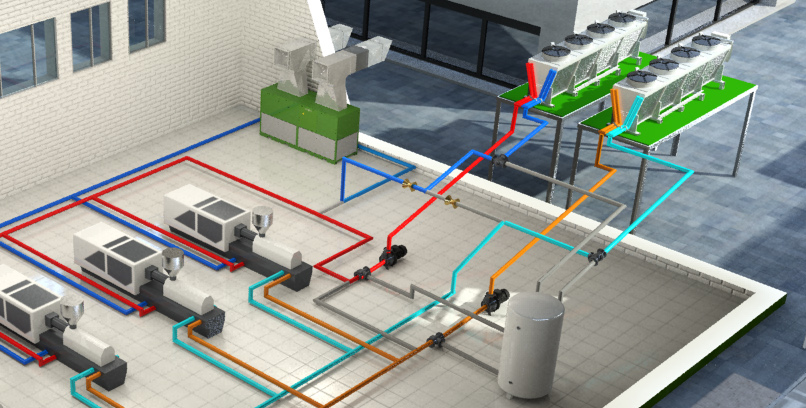

Integrated solution with a second

Installation of a second

- During the hot seasons

the free-coolers provide cooling for the hydraulics of the inj.moulding machines; - During the cold seasons

one free-cooler provide cooling for the moulds, the secondfree-cooler keeps on cooling the hydraulics of the inj. moulding machines.

Benefits:

- Higher energetic efficiency (the fluid in the high temperature circuit requires a lower power consumption);

- better temperature control of the hydraulic oil (constant temperature along while year)

Annual energy saving can be up to 90% !

Integrated solution with FCE self draining

- With the self draining solution glycol is not necessary.

- The FCE self daining

free-cooler is installed in outdoors and operates automatically when ambient air is sufficiently cold; this providesa pre-cooling of waterin the free-cooler reducing the operating time of the compressors. - When the system is not working

or in case of black-out, the FCE unit automatically drains the water preventing freezing, even if no glycol has been added to water.

Benefits: Energy Saving

the free-cooler has no compressor and uses ambient air to directly cool water.- reduced environmental impact as no glycol is necessary.

Annual energy saving can be up to 90% !