Individual temperature control of the users

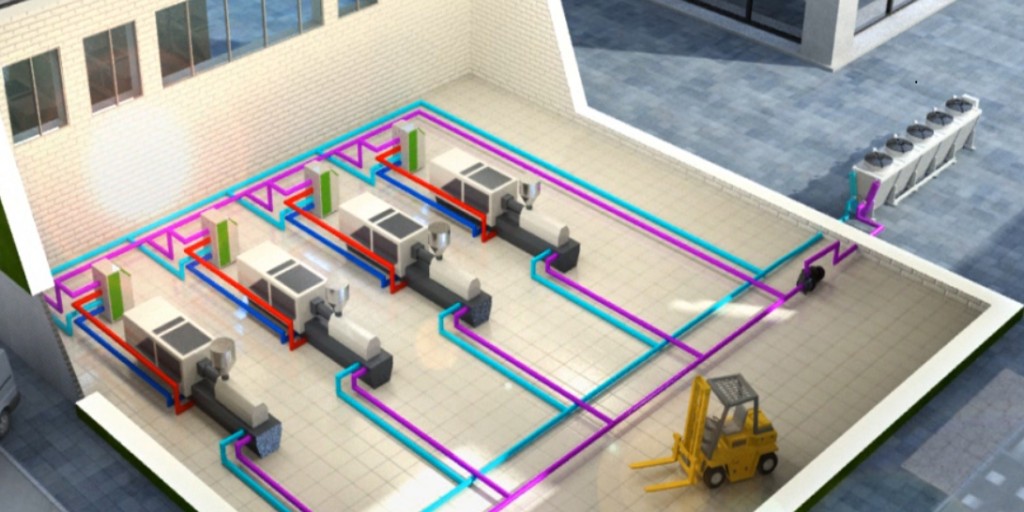

This kind of circuit is specifically intended for systems where independent temperature control is necessary for each user circuit:

- Temperature control units have to be installed for each user to provide independent temperature and water flow.

- Minibox, water cooled units, for installation side by side to the user machine.

- Minibox units can be used to chill and temperature control one or two independent circuits.

- A centralized

free-cooler provides cold water/brine to all the temperature controllers, Minibox units and to the hydraulic circuits of the injection moulding machines.

Benefits:

- Maximum flexibility to manage independent temperature and flows

- Accurate temperature control

- Accurate quality of the moulded pieces

- Optimized cycle times and higher productivity

- Higher energy efficiency in comparision with a centralized circuit (dedicated cooling for each user)

- Simplified installation of the water pipe circuit

- Energy savings:

— it is possible to inlcude free cooling operating mode on the moulds circuits The free-cooler is automatically switched to a lower temperature when ambient air is sufficiently cold; this providesa pre-cooling of water/brinein the free-cooler reducing the operating time of the compressors of the MINIBOX chillers; this option is available in two versions:

— Energy recovery by means of a direct mixing of waterfrom the free-cooler with process water for the moulds

— Energy recovery by means of an indirectfree-cooling mode; in this case process water is chilledby the free-cooler water/brine through a heat -exchangerThe free-cooler has to be installed outdoors;- two versions are available:

—Self-draining “FCE”Free-cooler (working without glycol)

— “FC”Free-cooler, which has to be used with glycol to prevent freezing, if ambient temperature can drop below 0°C

Benefit: Energy Saving

the free-cooler has no compressor and uses ambient air to directly cool water/brine