Supervision of process parameters system Pl@ntVizor

Now systems for automatic manufacture control are very actual and useful.

The primary goal of such systems is production output supported with constantly

high quality. It is achieved thanks to supervision of process parameters and

possibility

Specifications to automated management systems:

- Constant checkout of all setting parameters of production process

- Visual data display

- Ergonomic interface

- Easy to use the equipment

- Possibility of the data analysis for any period of time.

Green Box Company offers its clients the development of PlantVisor system of visualization and management for supervision of both existing and newly installed complex of cooling systems.

Main features:

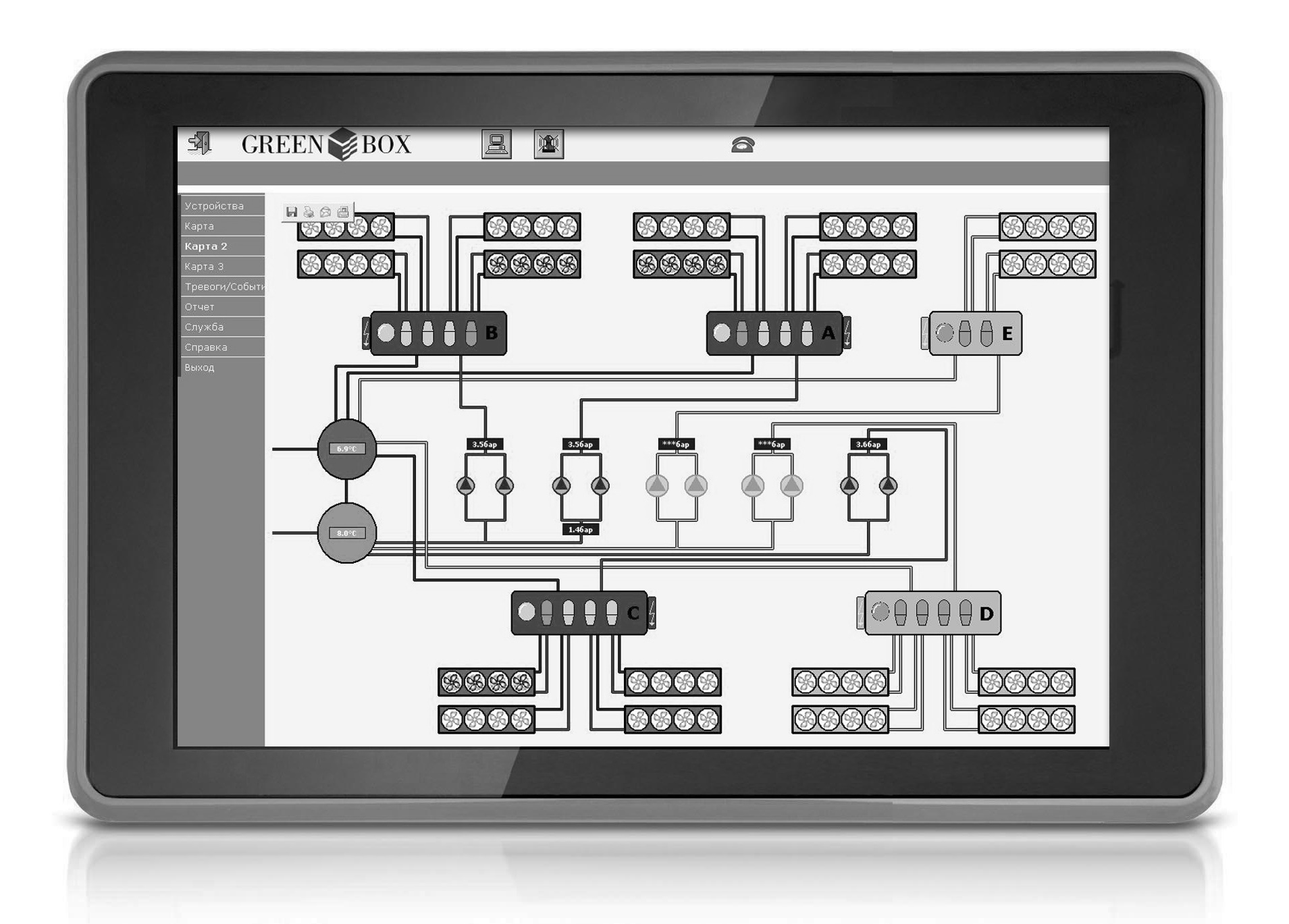

Full correspondence to the shop lay-out adapted for the best visual perception;

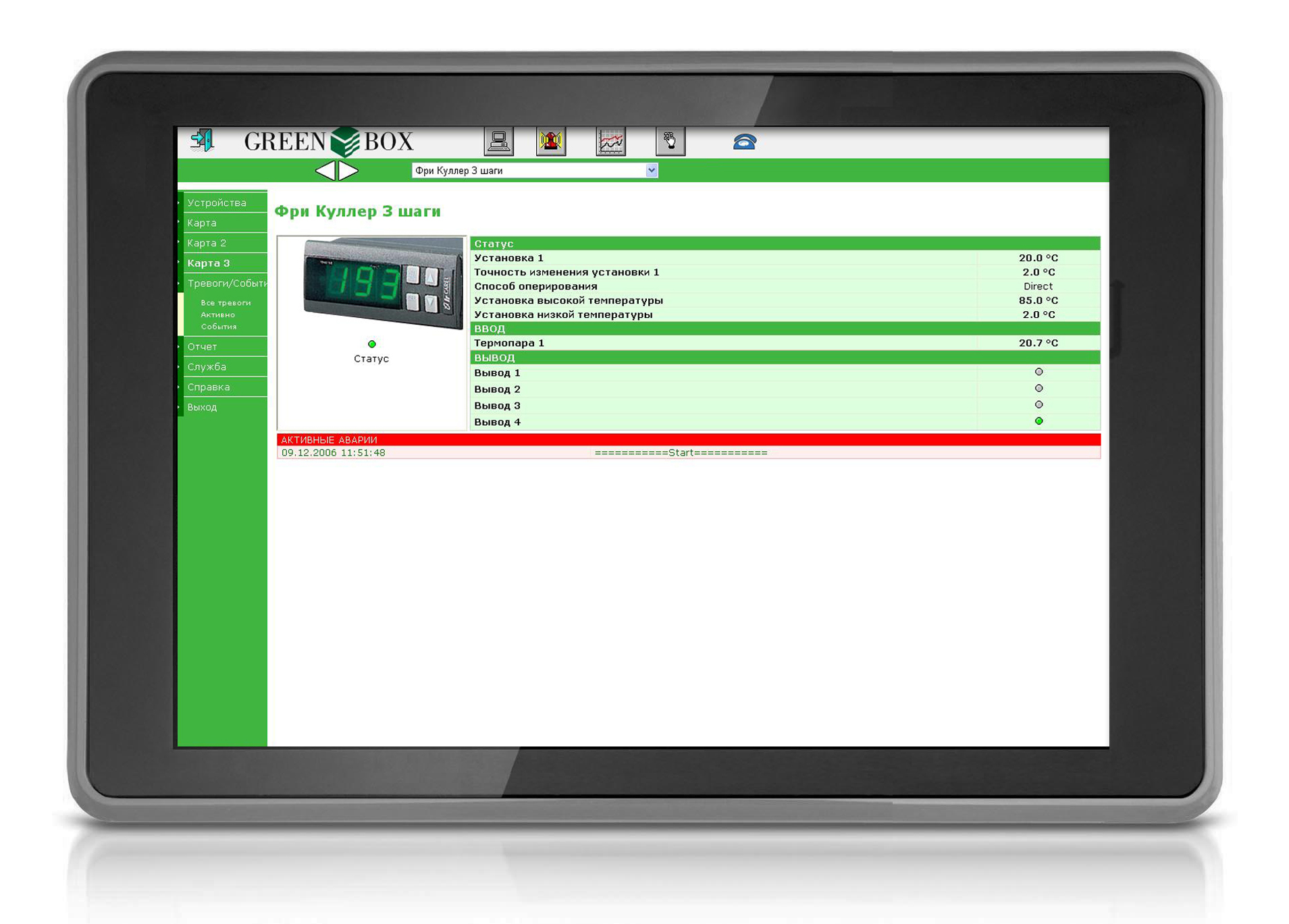

Management and control of each item of the equipment;

Updating of PlantVisor software according to expansion of cooling system;

Multilanguage support;

Constant monitoring of key parameters of cooling machinery in real time;

Storing of settings and recording history of events;

Possibility of any data finding for any interval of time for the subsequent analysis;

Graphic or tabular display of the data;

Printing of data and formation of reports in a file;

Access from an operator workplace through a local network of the enterprise or remotely through the Internet;

Administration of security policy and distribution of authority;

Possibility of automatic communication with the operator by fax, SMS or e-mail for sending of messages about working parameters and/or alarm signals.

One of the basic advantages is the possibility of parameter changes of working system or its separate parts with instant display of its reaction to the made changes.

The PlantVisor system is a very useful and convenient tool not only for the personnel employed it manufacture, but also for service engineers in our company. It helps them to react instantly to all possible deviations in operation of cooling machinery.