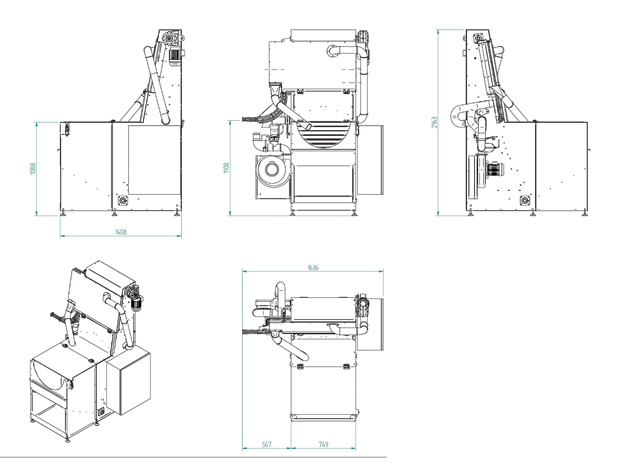

Orienting System

Vertical Gravitational Orienting System

This machine has been specifically designed to orient and introduce caps into the quality control system.

The Gravitational Orienting System is designed to be installed downstream of the production line and in particular downstream of our cap cooling system, the “Cap Cooler”.

The unit is constructed of stainless steel and materials approved for food applications.

It is suitable for closures with diameter between 25 and 38 mm and with height between 14 and 20 mm.

Special versions available on request for closures with different dimensions.

The unit is suitable for 150000 pieces per hour approx and it includes:

- Collecting Hopper

- Gravitational Sorter

- Feeding System to Quality Inspection Unit.

Collecting Hopper

The collecting hopper must be placed at the outlet of the Cap Cooler. It works as reserve bin and it is very useful in the event of any short interruption during operation.

Gravitational Sorter

This is a special conveyor, which collects the closures at the bottom of the

collecting hopper.

The special conveyor moves the closures upwards till the position at which the

closures, which are oriented in the wrong way, fall back into the collecting

hopper. The closures which are correctly oriented come to the top of the

conveyor.

Feeding system to the Quality Control Unit

When the closures reach the upper part of the conveyor, a blower blows the closures to the outlet, which feeds them in an oriented way to the conveyor of the quality control system.

|

Tecnical data

|

||

|---|---|---|

| Power of the feeding system blower | kW | 0.55 |

| Gearmotor power | kW | 0.37 |

| Volume of the collecting hopper | l | 230 |

| Required ground space | sm | 235 |

| Colour | RAL | 9010 White |

| Net weight | kg | 280 |

| Voltage | V - Hz | 380 - 415V/3/50 Hz 380 - 460V/3/60 Hz |

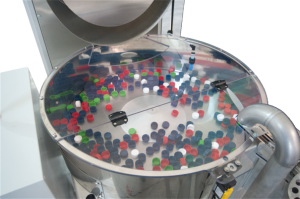

Centrifugal Orienting System

The unit is suitable for production up to 50000 caps per hour.