Temperature control unit Greencasting for the aluminium die-casting

GREENCASTING TEMPERATURE CONTROLLERS: HE FUTURE

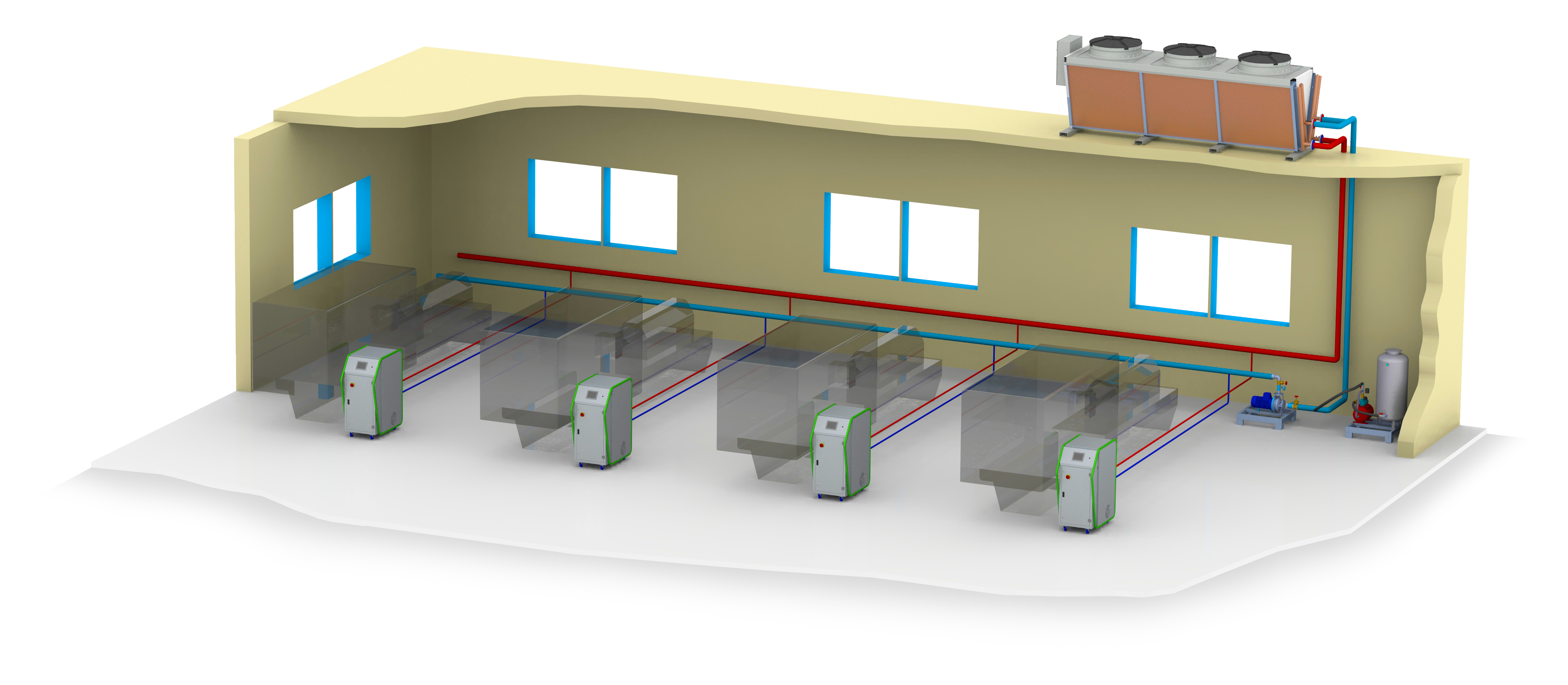

Greencasting the range of innovatory temperature control units of the GREENCASTING series gives Green Box a leading role in the world of the aluminium die-casting.

The complete control of the temperature

The completely new cooling system (patent pending) reduces to minimum the electrical energy consumption.

Main features:

- The process is completely controlled by a PLC.

- Pressurized water at 180°C

- Minimum electrical consumption: less than 2,35 kW of electrical energy in the cooling phase

- High temperature: operating temperature up to 180°C

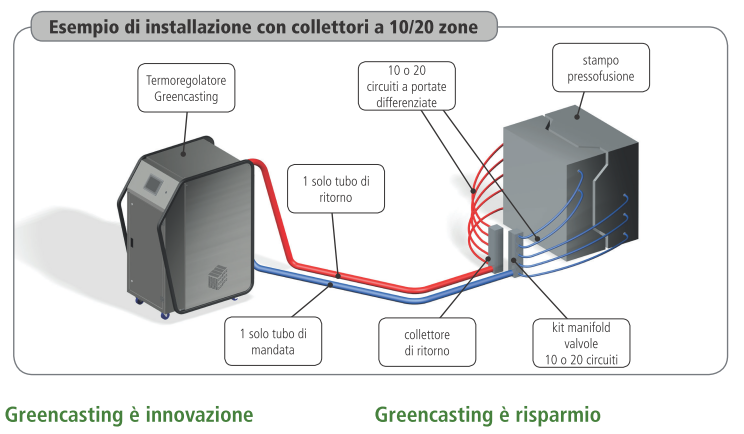

- Multizone unit: 10/20 independent zones of control of the mould temperatures

- City water: softened water can be used, but also city water.

- Stainless steel cabinet

GREENCASTING is innovation:

- Innovative cooling system

- Extremely high operation flexibility

- Simple installation

- 180°C max operating temperature

- Immediate commutation between heating and cooling phase and vice versa

- The lowest electrical energy consumption

GREENCASTING is savings:

- Softened water can be used, but also city water

- Negligible use of compressed air

- Minimum thermal losses

- Minimum number of temperature control units per casting machine

- Minimum quantity of connecting hoses

- No compressed air in the piping system

Options:

- 10 way remote distribution manifold

- 20 way remote distribution manifold

- 10/20 temperature probes in the return manifold

- 10/20 pressure sensors in the return manifold